PRO-TEX Enclosures

PRO-TEX offers a wide variety of features

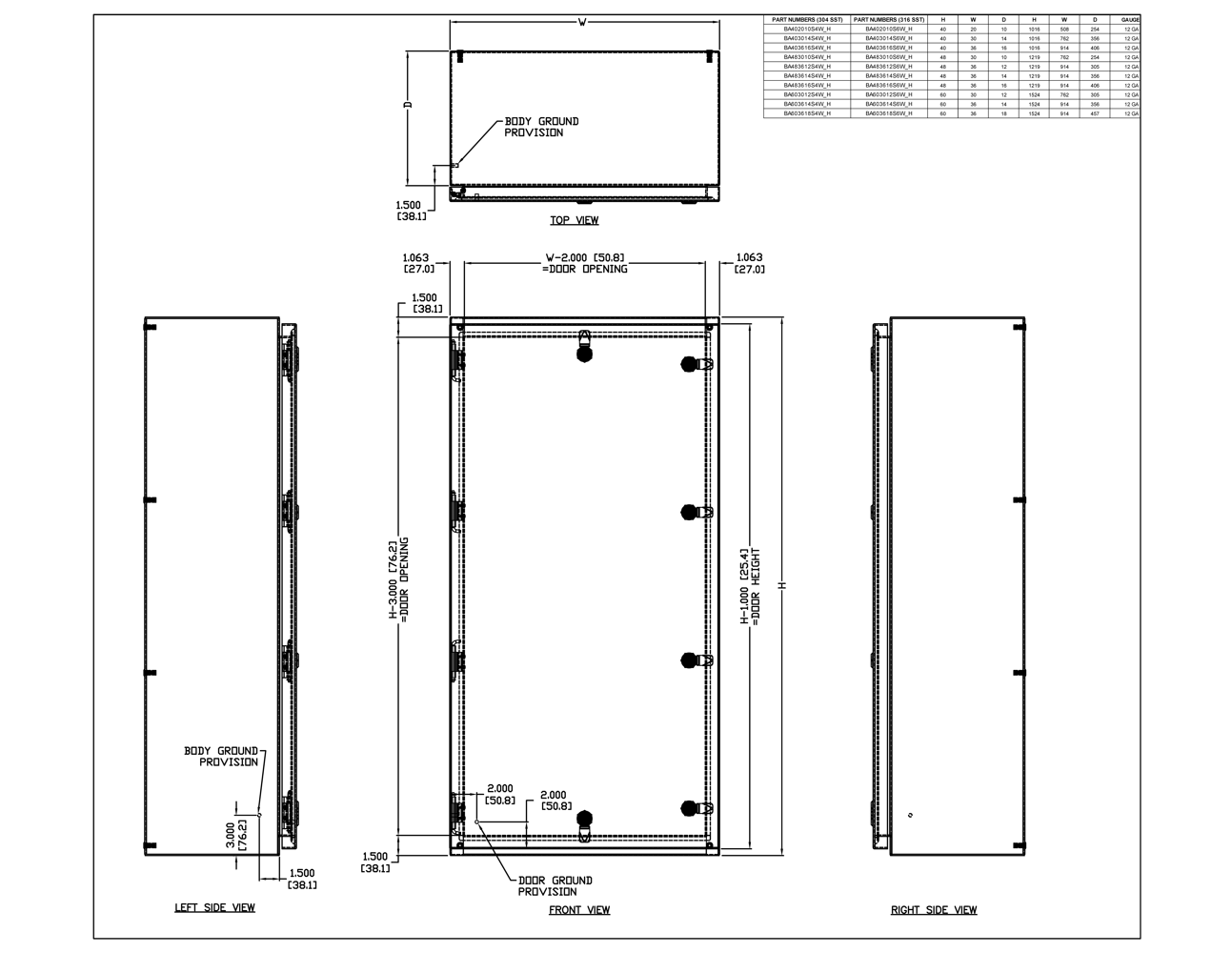

PRO-TEX enclosures come in various sizes, and of course, can be custom-crafted to your exact specifications, including cutouts and brackets.

PRO-TEX enclosures:

- ATEX-IECEX approved enclosures

- Intrinsically safe for use in hazardous & harsh areas

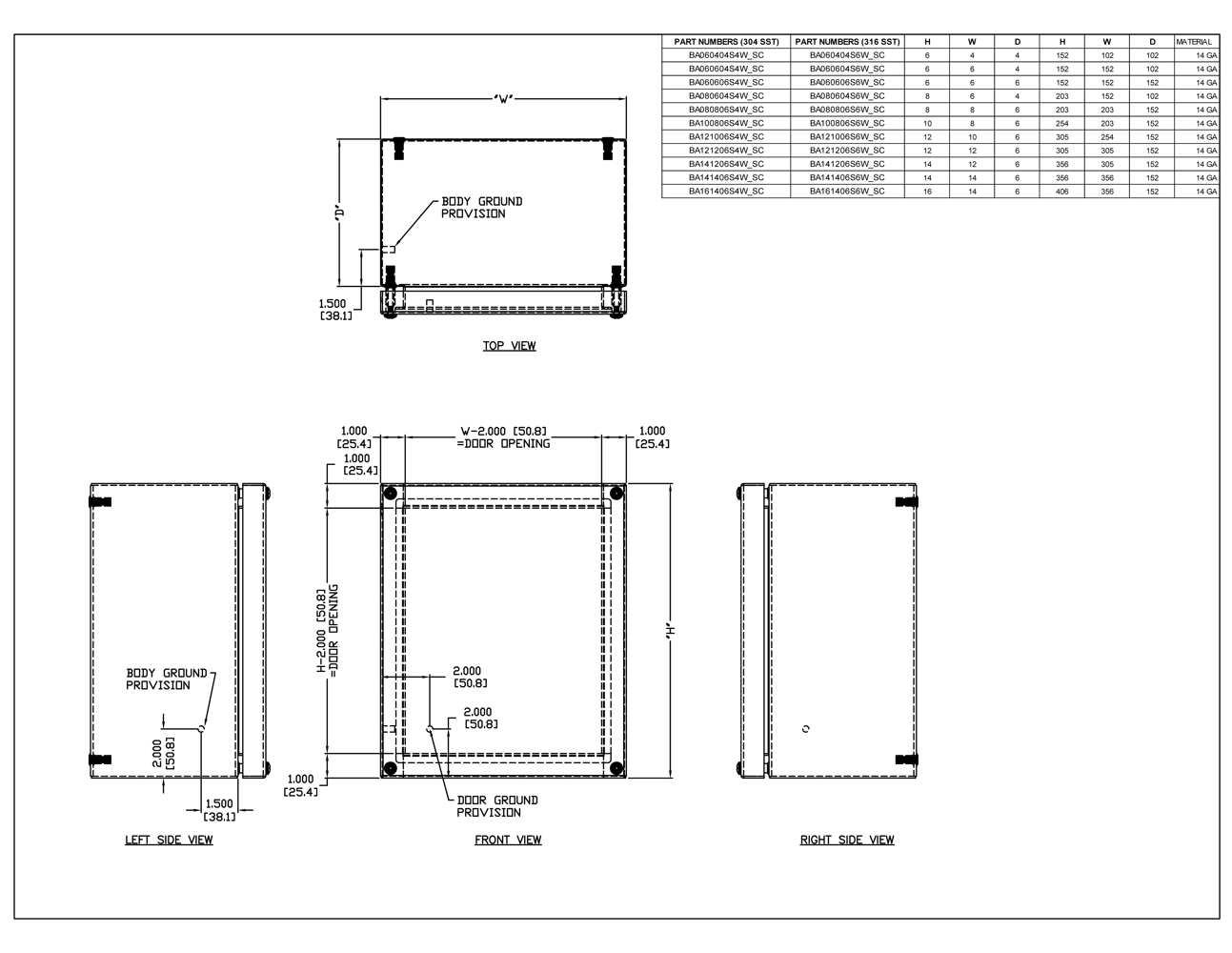

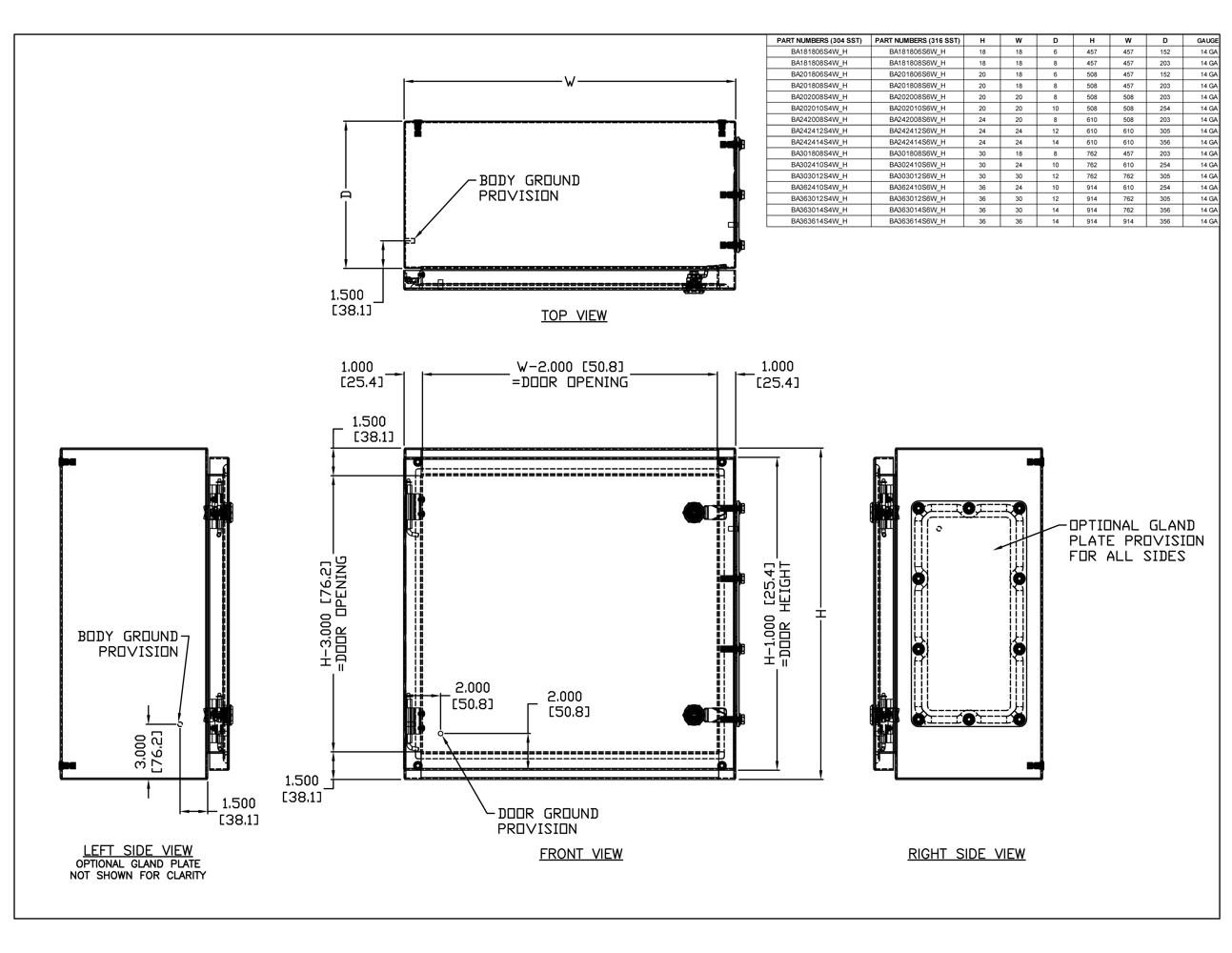

- Range in size from 6”H x 4”W x 4”D (152x102x102mm) up to 80”H x 48”W x 24”D (2032x1016x609mm)

- Crafted from 304 and 316L stainless steel with a brushed #4 (Ra40-Ra25) finish

- Include integral stainless steel earth grounding locations on the interior and exterior

- Operate in temperatures between -25°C ≤ Ts ≤ 145°C

- Provide standard IP66 and NEMA 4X protection

View our Hinge & Screw Cover Enclosures

Make PRO-TEX enclosures your own. Bison offers a wide array of options to customize your PRO-TEX enclosure:

- Silicone gaskets for doors, covers, and gland plates in both seamless foam in place and strip gaskets

- Wall mount or free standing with removable mounting brackets

- Removable hinged and screw-mounted doors and covers

- Removable Gland plates can be placed on any side of the enclosure body. Plates offered in a range of sizes.

- Welded NPT coupling penetrations available

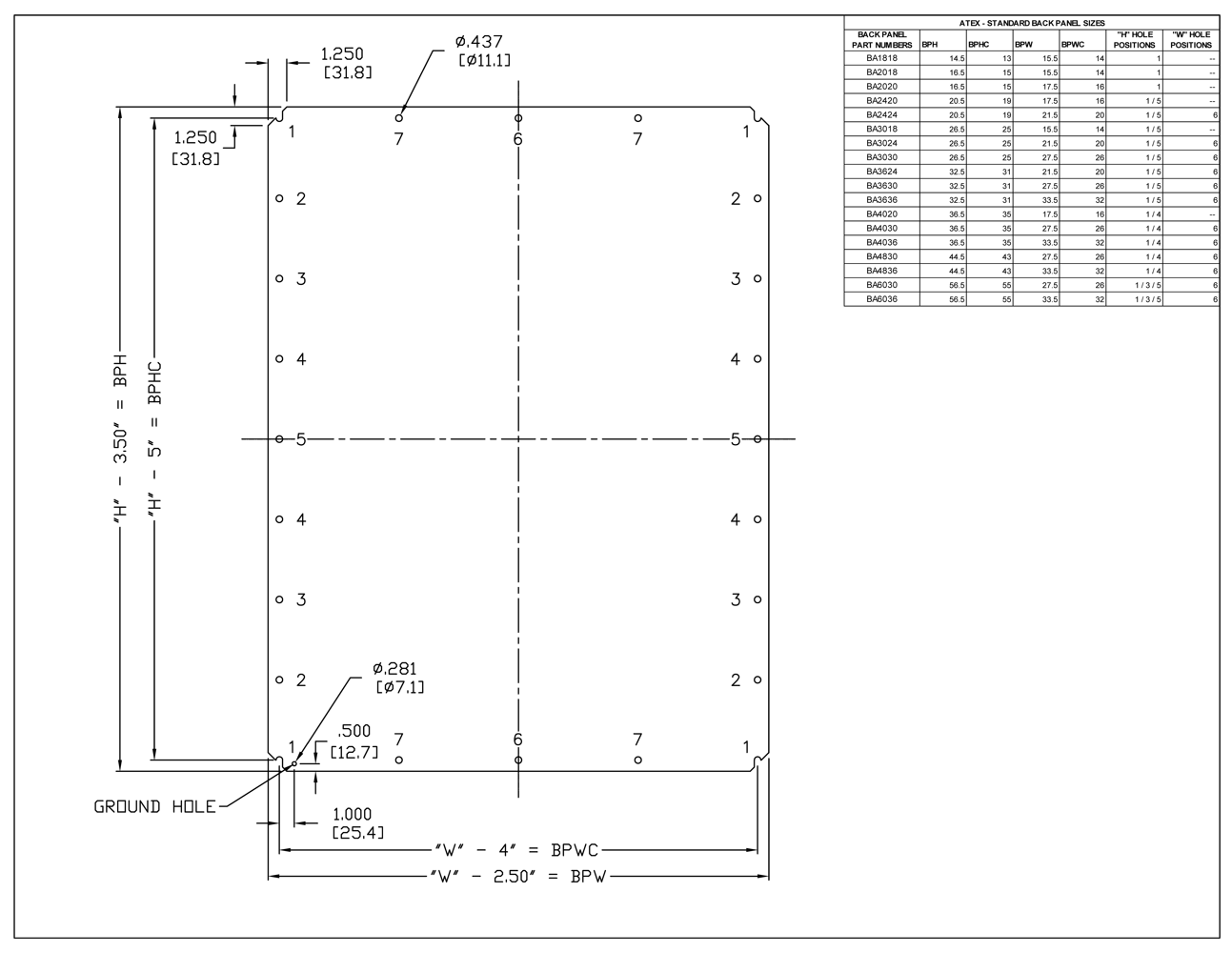

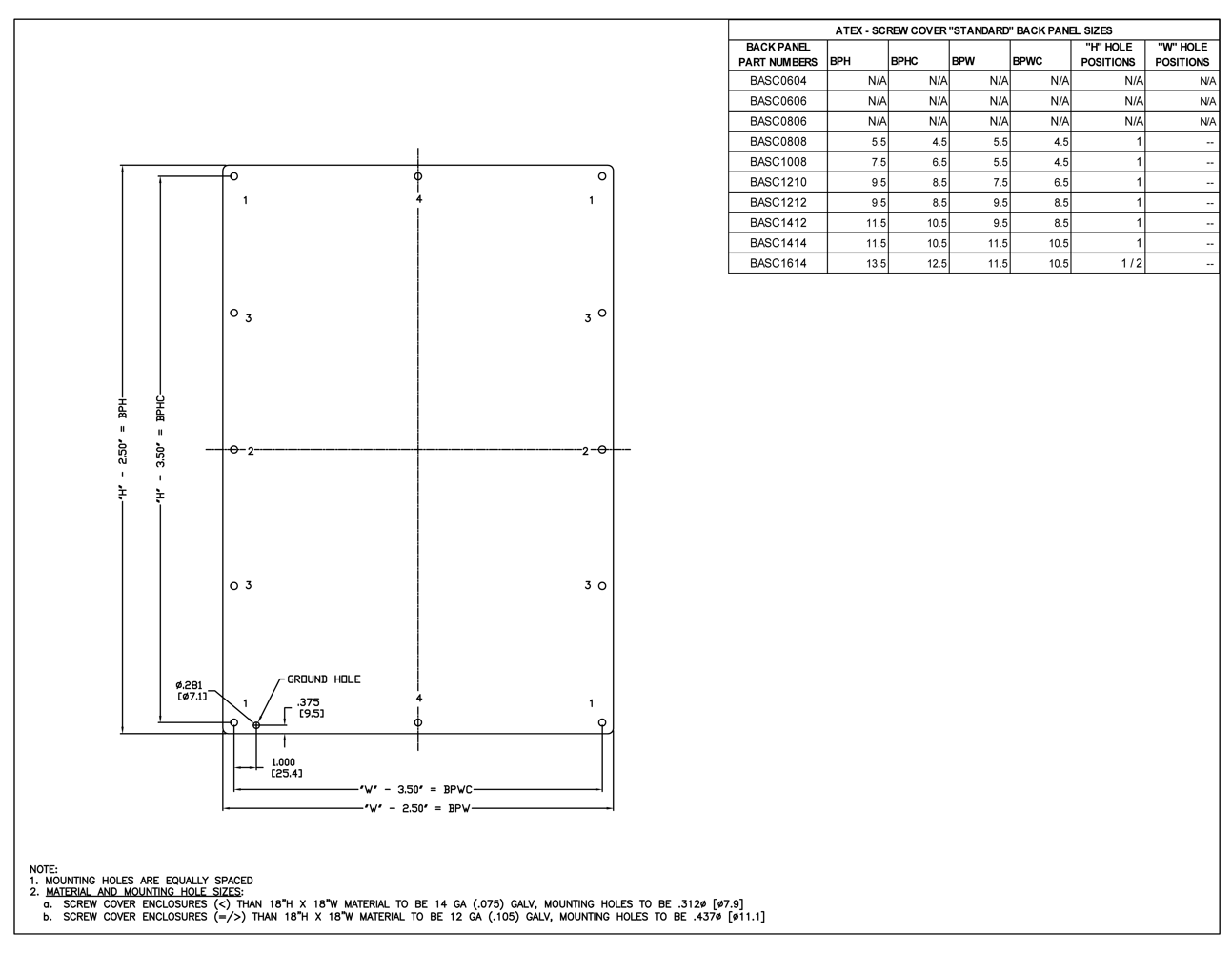

- Internal equipment mounting panels in aluminum, painted carbon steel, stainless steel, and galvanized carbon steel

PRO-TEX enclosures withstand heat, resist cold, and stand up to the worst kind of punishment a working environment can dish out. Use PRO-TEX while working in:

- Chemical and petrochemical industries

- Offshore industry

- Grain and flour mills

- Food and beverage

- Water and wastewater

- Automotive

- Transportation

- Alternative energy

- Pharmaceutical industry

Make Bison your manufacturer of choice

The new PRO-TEX line is yet another reason to make Bison Profab your manufacturer of choice. From design to finished product, we strive to maximize proficiency, efficiency, and quality.

Bison ProFab uses cutting-edge manufacturing software to design and draft your enclosure. This process confirms the proper fit, finish, and functionality of your product. Bison’s highly experienced and skilled sheet metal craftsmen utilize sophisticated, state-of-the-art equipment to fabricate that design into reality. Our in-process quality control and thorough final inspection ensure you receive exactly the product you ordered – before it is wrapped, palletized and shipped.