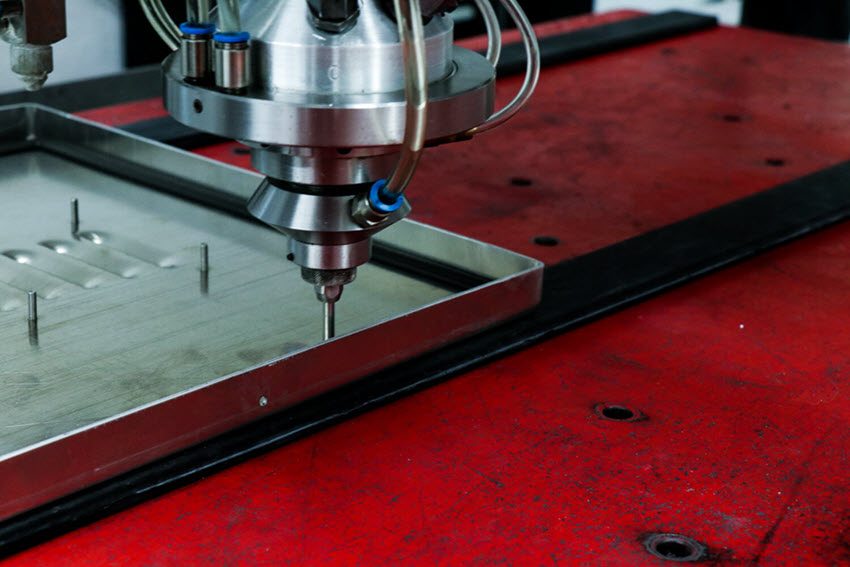

CNC Foam Gasket for Enclosure Door & Cover Sealing

The Rampf CNC foam gasket machine is perfect for enclosure door & cover sealing. This formed-in-place foam gasket machine is excellent for the single one-off to one million part production runs.

Its easily programmable and low maintenance coupled with the Raku-Sil37 silicon gasket is the ideal application for all of your enclosure door and cover sealing needs.

Raku-Sil37 is the trade name for the two-component silicone system for manufacturing of flexible silicone elastomers and silicone foam sealing, which are applied directly onto the part by using FIPFG (formed-in-place foam gasket) technology.

10 Good reasons for using Raku-Sil37:

- Raku-Sil37 systems can be used at a constant temperature up to +180° C, for special types up to +250° C and temporary up to +350° C.

- Raku-Sil37 systems are closed-cell and therefore do not absorb water.

- Raku-Sil37 systems are highly resistant to many chemicals.

- Raku-Sil37 systems are hydrolysis stable and therefore suitable for the use in tropic or damp environment.

- Raku-Sil37 systems keep greatest possible flexibility even down to -60° C.

- Raku-Sil37 systems are tack-free in 2 - 30 minutes depending on the thermal condition. An oven can reduce the reaction time considerably, but that is not always necessary.

- Raku-Sil37 systems are processed using a 2-component mixing and metering machine and can be adapted flexibly and quickly to other parts for sealing application at any time.

- Raku-Sil37 systems develop a cross-linked structure which is extremely resistant to environmental effects such as humidity, dust and temperature.

- Raku-Sil37 systems possess exceptional long-term behavior and have almost 100% resetting ability, even after many years of continual use.

- Raku-Sil37 systems are in some cases also suitable for direct contact with food.